The highest quality screen printing in Portland.

Serving customers across the U.S.

The highest quality screen printing

in Portland, for customers across the U.S..

Screen Printing Orders

Print on Most

Anything You Want

Quick Turnaround

Delivered Nationwide

Eco Friendly

Inside & Out

Creative Services

We’re Here to Help

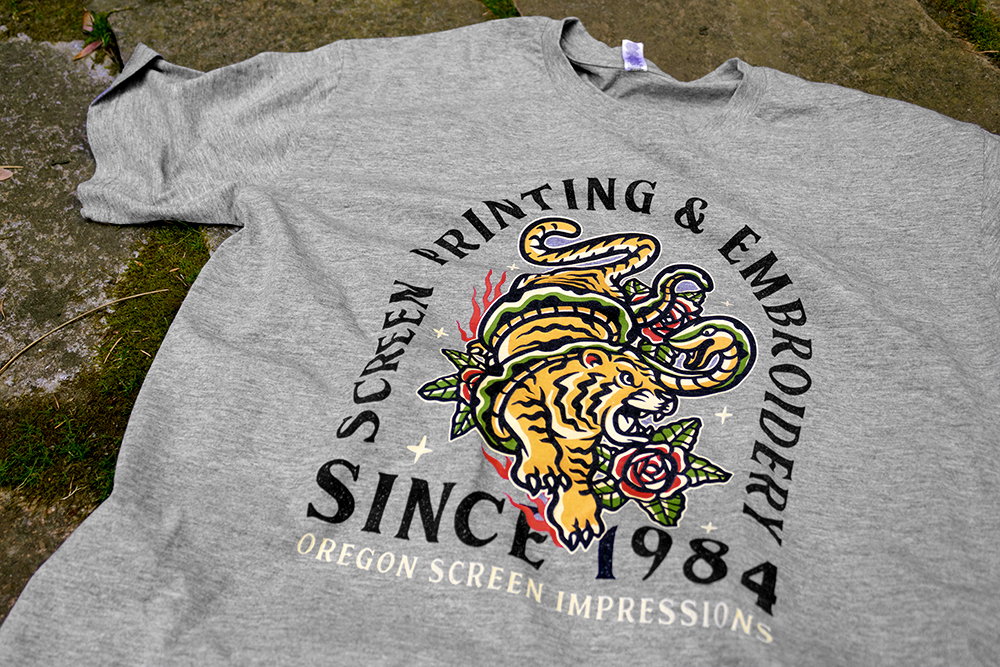

Print on almost anything.

From t shirts to skateboards, pizza boxes to basketballs, we have printed it all.

T Shirts

Custom t shirts are our bread & butter.

Jackets

Gear up your shop with custom jackets.

Sweatshirts

And sweatpants! Make a cozy impression.

Product Boxes

Make an impact upon arrival.

Cool Totes

Let them carry you everywhere they go.

Posters & Flatwork

Handheld to oversized, print your work of art.

Outdoor Gear

For all kinds of gear and wear.

Humble or grand, our team will make it happen.

With the most advanced printing technology and the kindest, most informed people, we’ll work with you to create exactly what you want. When you start an order, one of our project managers will reach out to ensure every detail is dialed in and the process goes like clockwork.

“I have nothing but great things to say about Sarah & the whole team at OSI. They have patiently addressed all of my questions/concerns and took special care to make sure my print project turned out beautifully. I highly recommend them for any of your printing needs!”

-Cass

“We have been using OSI for a number of years now and appreciate their super fast, knowledgable customer service and willingness to source t-shirt fabric options that aren’t something they typically carry. Their screen printing quality is great and lasts for years even with weekly usage, even with intricate designs!”

-Josh

“We used Oregon Screen Impressions for a variety of screen-pressed articles for a company event. Quality was top notch, and Camille was a big help in selecting articles and made the whole process as smooth and as efficient as possible. Would definitely recommend Oregon Screen Impressions to anyone in need of print services in PDX!”

-Ronald

Trusted by

Reclaiming the Future

Did you know if properly cleaned and cared for, screens can be reused quite a few times? We were the first screen printing company in the U.S. to install a self-contained screen cleaning and reclamation machine, which maximizes efficiency and minimizes what goes down the drain.

Our Difference

Every one of our customers receives the same hands-on care. From the first email or phone call with your OSI rep to the production of your order, we’re here to ensure you’re happy with the result.

With 15 distinct presses, including our new 28-station press, we can handle even the most complex jobs efficiently and with the highest quality standard.

Have confidence that what you order is what we’ll print. A human being in our ink department will physically match the ink for your project to your specified PMS color.

We’re here for you. Making cool things for nice people is why we started this business over 40 years ago. Utilize our skilled team of experts to get exactly what you want (or something even better).

We serve the entire United States, but if you’re local to Portland, save on shipping by picking up your order. Stop in to say ‘hey’ while you’re here.

We can save you time by prepping your products to go straight onto store shelves. Let us apply hang tags, handle the folding, and poly bagging. We can even do sew on labels and interior branding to fully customize your goods. Learn more about our Finishing Services.

Looking for merch fulfillment service? We handle warehousing, order fulfillment, shipping, and customer service, including returns and exchanges for many of our clients. We can integrate with your current store or build you a new one. Learn more about our fulfillment solutions.

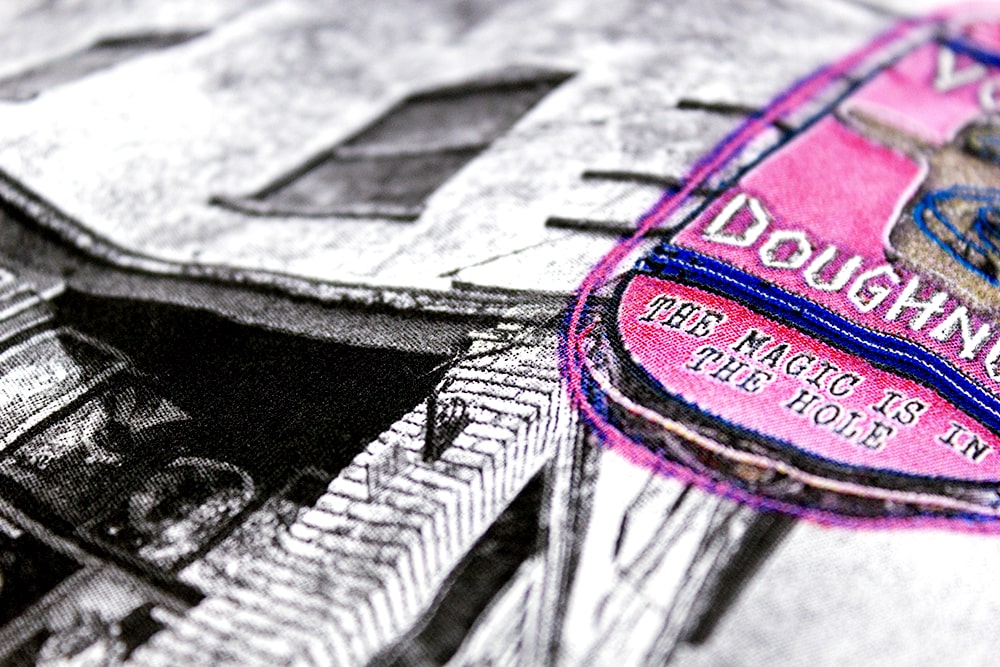

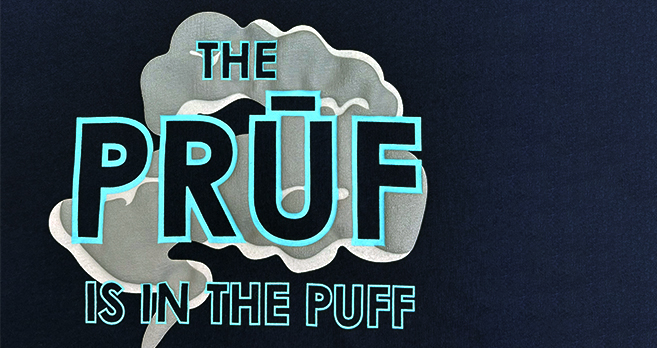

Techniques & special inks close-up.

Choose from a wide range of popular ink options to create a variety of effects.

Screen Printing FAQ

The art of screen printing has been around for hundreds of years. Screen printing refers to the process where ink is forced through a mesh screen onto a surface with the use of a blade or squeegee. The ink that passes through forms a printed image. Areas of the screen can be blocked out with a blocking stencil.

We can screen print as few as 24 pieces per design. Quantity price breaks are at 48, 72, 120 & 200 pieces per design.

Production times may vary depending on the services you’ve ordered and the time of the year, but our standard turnaround is approximately 10 business days.

Your Project Manager will give you an estimated timeline with your quote. If you have a firm, in-hand date for an event, be sure to let us know at the beginning of the quoting process so we can confirm our ability to meet your date. We may be able to accommodate rush requests on a case by case basis.

Find our Art Guidelines here. Your project manager would be more than happy to review your file to ensure it meets our guidelines. We also have a talented creative services team who can assist in creating new art or updating existing files.

Artwork can be submitted directly by email or our online form. For larger files, follow the upload instructions here.

As an experienced, full-service decorator, we can source nearly any garment. We will supply the blank apparel and work with you to find the perfect options for your project. We do not work with customer provided garments.

Reach out to us about what you’re looking for. A project manager will be in touch with options for you. Or, browse product catalogs from some of our most popular manufacturers to get started.

Print sizes vary by substrate (i.e. what we’re printing on) and the art. Your OSI rep can help you best determine the print area for your project.

For reference, however, a left chest print on a top would be about 3.5″ wide depending on the height. A front print is usually about 8.5″ to 11″ wide, depending on the height and whether the print is going on a women’s tee or a unisex tee. Back prints are typically 10.5″ to 12″ wide, depending on the heigh and whether the print is going on a women’s tee or a unisex tee.

The largest size we can screen print on flatwork/posters is 38″ x 40″ (one color only). The largest size we can screen print on a t shirt is dependent on the size of the garment and whether you want to print over seams and hems. For the most accurate information, discuss your needs and vision with an OSI rep.

Due to the limitations of screen sizes and pre-fabricated apparel, we are unable to do a literal ‘all-over’ print. However, our creative services team would be happy to help you find a look that gives you the effect you desire.

Working with one of our vendor partners, we can certainly help you with your sublimation printing project.